Cognitive electronic fuel injection diesel engine

2020-10-28 From: Weihai Changtai Shipbuilding Company Browsing times:46

MAN-B&W diesel engine

1) Fuel injection common rail control system

Difference from tradition: The plunger of the high-pressure oil pump is no longer driven by the camshaft, but by the main lubricating oil, which drives the plunger up and down by pushing the internal piston of the high-pressure oil pump. Each cylinder is set on the cylinder head platform, and the main lubricating oil comes from the lubricating oil system of the diesel engine.

Drive without crankshaft: Different from traditional MAN B&W MC models, the main lubricating oil not only lubricates moving parts and cools high-temperature parts, that is, to lubricate the main bearing crosshead bearing crank pin bearing and cool the piston head, but also passes through a self-cleaning function fine filter provided by the main engine. Under the boost of the diesel engine's built-in booster pump, this main lubricating oil is pressurized to 20 MPa, and then to two large nitrogen charging accumulators in each cylinder's high-pressure oil pump to maintain the constant pressure of the high-pressure lubricating oil system and reduce pressure fluctuations.

How to share fuel rail: The high-pressure lubricating oil is quickly controlled by the electronic control valve NC to drive the piston to move up and down quickly, which instantly increases the pressure of the high-pressure oil pump plunger, causing the oil pressure to rise to generate high pressure (75-120 MPa). The electronic control solenoid valve NC is controlled by the microprocessor control program system ECSP, and its fuel rail refers to the power lubricating oil that drives the high-pressure oil pumps of each cylinder coming from the common rail pipe.

Injection control: The fuel injection of each cylinder's high-pressure oil pump is initiated by issuing commands based on the comprehensive information of the diesel engine condition analysis system ECA and the control operating system OMCP, and is atomized through the fuel injector.

2) Exhaust valve common rail control system

Difference from tradition: The structural form of the exhaust valve common rail system is similar to that of the fuel common rail.

Opening and closing control: The electric solenoid valve NC controls the power lubricating oil, and its opening and closing are controlled by the microprocessor control program system ECSP according to the combustion condition of the cylinder, which sends signals to control the opening and closing of the exhaust valves of each cylinder.

Performance and advantages: By using electronic control of the exhaust valve opening and closing, not only can the exhaust valve strike the valve seat at a uniform speed, but also the friction and noise when the valve is closed are reduced, effectively reducing emissions and controlling the exhaust temperature of the host.

2. Wartsila diesel engine

1) Fuel injection common rail control system

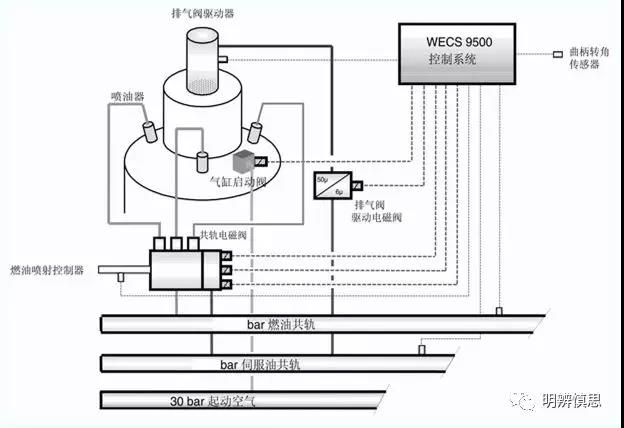

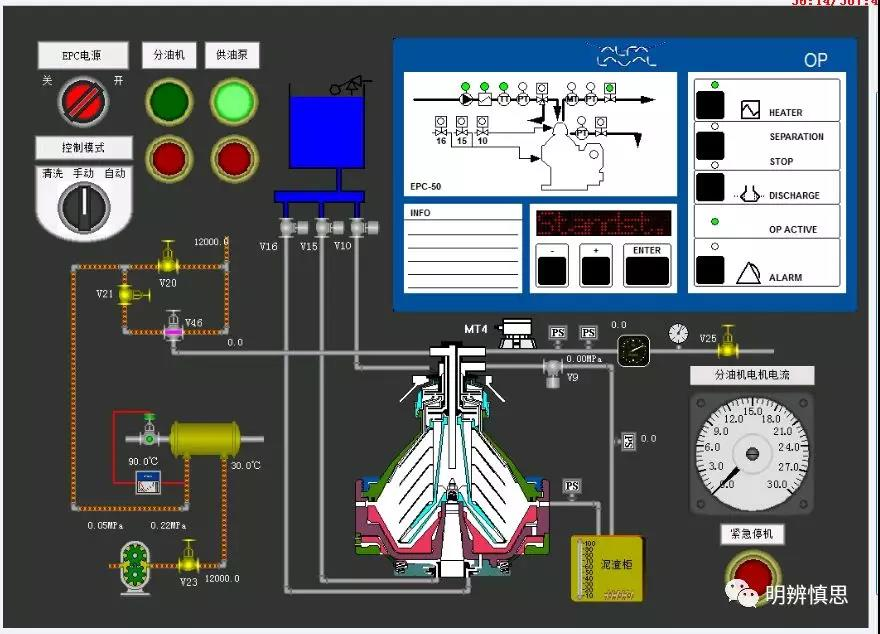

The difference between Wartsila and MAN-B&W: The RT flex model has two common fuel rails (injection and exhaust valve control), and the fuel injection control unit is driven by 20 MPa servo oil. The trigger signal of the servo oil comes from the cylinder control unit of WECS-9520. The cylinder control unit measures the position and load of the crankshaft through a crankshaft angle sensor, and then judges and calculates to select the timing for fuel injection.

How to use common rail fuel: The crankshaft drives the high-pressure common rail fuel pump to pressurize the fuel to 1000 bar through a triangular cam, and then flows from the high-pressure fuel pipeline to the high-pressure common fuel supply pipe. The fuel is then injected and controlled by the volumetric injection control unit (ICU).

The design of this system allows the chief engineer to reset FQS and VIT using the auxiliary unit of WECS through feedback information from the main engine. Especially when the diesel engine is running at low load, the WECS-9520 control system can control three injectors to close one or two to reduce fuel injection, maintain good low load operating characteristics, and reduce emissions.

2) Exhaust valve common rail control system

Driving principle: The working principle of the exhaust valve hydraulic driving system is to use 200 bar lubricating oil as the servo oil to drive the exhaust valve and cylinder starting valve device. It is controlled by a Dannick variable displacement pump with a shaft belt triangular cam, which does not require directional operation. The high-pressure servo oil pump injects hydraulic oil into the hydraulic manifold, and the WECS-9520 sends a signal to control the common rail valve (Rail vavle) to drive the exhaust valve through a hydraulic actuator.

2、 Daily management precautions

1) Maintenance of electronic components: Any abnormality in the electronic control components of the common rail oil pressure system may cause abnormalities in the main parameters of the diesel engine. Regular disassembly, cleaning, and inspection should be carried out according to the instructions.

2) Ensure sealing to prevent dripping: The pressure of the common rail oil pressure system is high, and it is necessary to ensure the sealing of fuel and servo oil during operation. Regular maintenance is required, and seals that are prone to aging should be replaced regularly.

3) Reduce vibration sources: Wear and looseness of moving parts in diesel engines can exacerbate vibration, thereby affecting the looseness of electronic control diesel engine fuel injection control units, exhaust valve control units, cylinder electronic units, solenoid valves, sensors, and their connection points.

4) Ensure ventilation: A suitable ambient temperature is also an important condition for ensuring the normal operation of electronic control equipment.

5) Control and treatment of oil quality: As a power oil, servo lubricating oil should meet the quality requirements for high-pressure operation in terms of temperature, viscosity, cleanliness, etc; The temperature, viscosity, cleanliness, etc. of fuel can also affect the operation of solenoid valves and sensors, and should be cleaned and treated regularly.

Product

Product

Related Articles More>>

- The Chinese New Year is approaching, and the cold winter is the twelfth month. The weather is cold, but people are warm.

- Sending Warmth and Caring in the Cold Winter | Changtai Ship launches the 2021 "Sending Warmth in Winter" campaign

- Thank you for accompanying me all the way—— Changtai Shipbuilding Co., Ltd. Annual Summary Meeting

- The prevention and control of the epidemic cannot be delayed